light Ram 1500 2013 Get to Know Guide

[x] Cancel search | Manufacturer: RAM, Model Year: 2013, Model line: 1500, Model: Ram 1500 2013Pages: 196, PDF Size: 9.66 MB

Page 105 of 196

Using HomeLink®

• To operate, press and release the programmed HomeLink

®button. Activation will

now occur for the programmed device (i.e., garage door opener, gate operator,

security system, entry door lock, home/office lighting, etc.,). The hand-held

transmitter of the device may also be used at any time.

WARNING!

• Your motorized door or gate will open and close while you are programming the universal transceiver. Do not program the transceiver if people or pets are in the

path of the door or gate.

• Do not run your vehicle in a closed garage or confined area while programming

the transceiver. Exhaust gas from your vehicle contains Carbon Monoxide (CO)

which is odorless and colorless. Carbon Monoxide is poisonous when inhaled

and can cause you and others to be severely injured or killed.

POWER INVERTER

• A 115 Volt, 150 Watt power inverteroutlet is located on the lower instru-

ment panel next to the climate control

knob. This outlet can power cellular

phones, electronics and other low

power devices requiring power up to

150 Watts.

• To turn on the power outlet, simply plug in the device. The outlet auto-

matically turns off when the device is

unplugged.

NOTE:

The power inverter is designed with

built-in overload protection. If the power

rating of 150 Watts is exceeded, the

power inverter will automatically shut down. Once the electrical device has been

removed from the outlet, the inverter should automatically reset.

WARNING!

To Avoid Serious Injury or Death DO NOT:

• insert any objects into the receptacles

• touch with wet hands

Close the lid when not in use. If this outlet is mishandled, it may cause an electric

shock and failure.

ELECTRONICS

103

Page 106 of 196

POWER OUTLETS

• The auxiliary 12 Volt (13 Amp) power outlets can provide power for in-cabaccessories designed for use with the standard “cigar lighter” plug. The 12 Volt

power outlets have a cap attached to the outlet indicating “12V DC”, together with

either a key symbol or a battery symbol.

• The auxiliary power outlets can be found in the following locations: • Lower left and lower right in the center of the instrument panel – if equipped

with a column or a eight-speed electronic shifter.

• Inside the top storage tray.

•

Inside the upper lid of the center

storage compartment — if equipped.

•Rear of the center console storage

compartment — Quad Cab®or Crew

Cab.

NOTE:

Do not exceed the maximum power of

160 Watts (13 Amps) at 12 Volts. If the

160 Watt (13 Amp) power rating is ex-

ceeded, the fuse protecting the system

will need to be replaced.

• Power outlets are designed for acces- sory plugs only. Do not insert any other

object in the power outlet as this will

damage the outlet and blow the fuse.

Improper use of the power outlet can

cause damage not covered by your new

vehicle warranty.

ELECTRONICS

104

Page 112 of 196

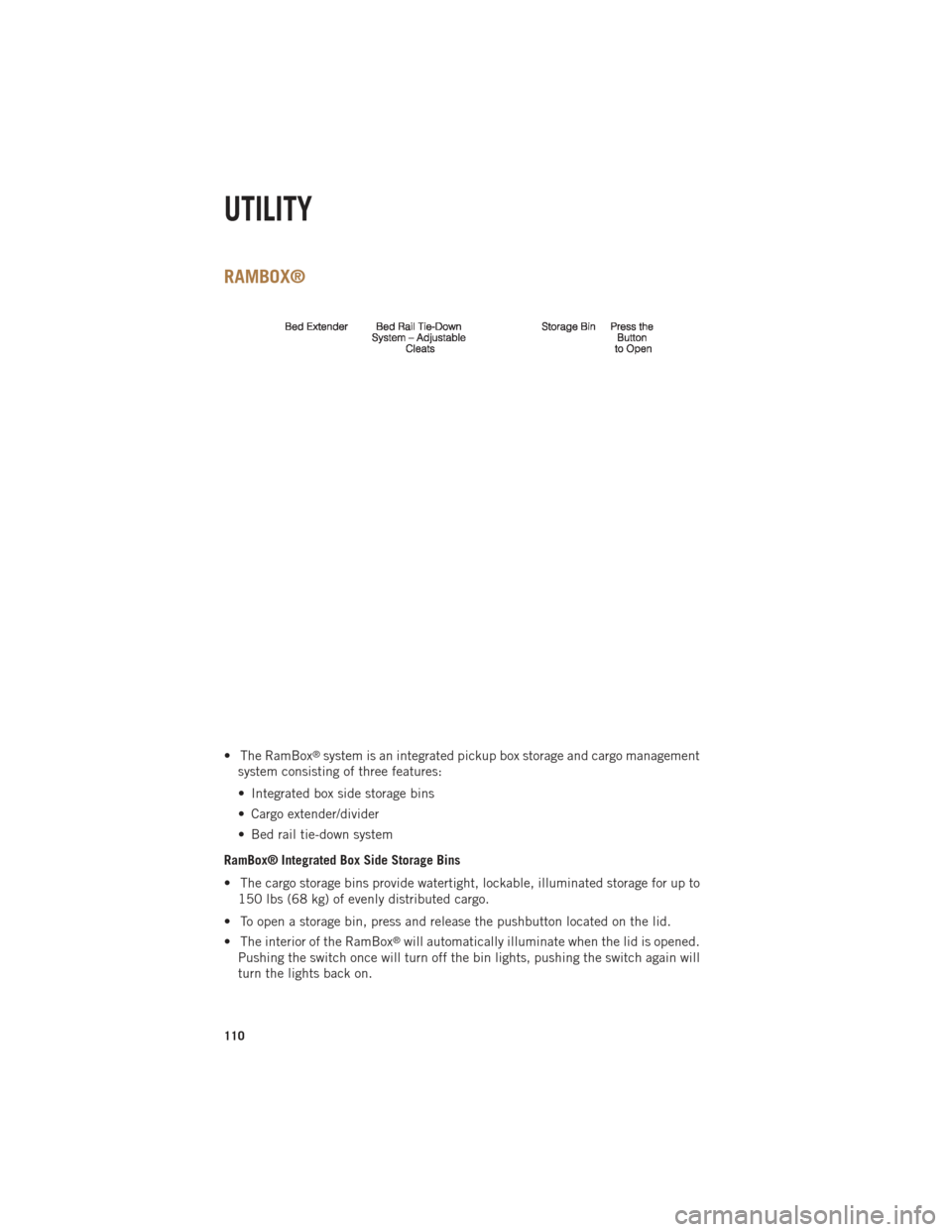

RAMBOX®

• The RamBox®system is an integrated pickup box storage and cargo management

system consisting of three features:

• Integrated box side storage bins

• Cargo extender/divider

• Bed rail tie-down system

RamBox® Integrated Box Side Storage Bins

• The cargo storage bins provide watertight, lockable, illuminated storage for up to 150 lbs (68 kg) of evenly distributed cargo.

• To open a storage bin, press and release the pushbutton located on the lid.

• The interior of the RamBox

®will automatically illuminate when the lid is opened.

Pushing the switch once will turn off the bin lights, pushing the switch again will

turn the lights back on.

UTILITY

110

Page 115 of 196

CAUTION!

• Failure to follow the following items could cause damage to the vehicle:• Assure that all cargo inside the storage bins is properly secured.

• Do not exceed cargo weight rating of 150 lb (68 kg) per bin.

• Leaving the lid open for extended periods of time could cause the vehiclebattery to discharge. If the lid is required to stay open for extended periods

of time, it is recommended that the bin lights be turned off manually using

the on/off switch.

• Ensure cargo bin lids are closed and latched before moving or driving

vehicle.

• Loads applied to the top of the bin lid should be minimized to prevent

damage to the lid and latching/hinging mechanisms.

• Damage to the RamBox

®bin may occur due to heavy/sharp objects placed

in bin that shift due to vehicle motion. In order to minimize potential for

damage, secure all cargo to prevent movement and protect inside surfaces

of bin from heavy/sharp objects with appropriate padding.

• The maximum load per cleat should not exceed 250 lbs (113 kg) and the

angle of the load on each cleat should not exceed 60 degrees above

horizontal, or damage to the cleat or cleat rail may occur.

WARNING!

•Always close the storage bin covers when your vehicle is unattended or in motion.

• Do not allow children to have access to the storage bins. Once in the storagebin, young children may not be able to escape. If trapped in the storage bin,

children can die from suffocation or heat stroke.

• In a collision, serious injury could result if the storage bin covers are not

properly latched.

• Do not use a storage bin latch as a tie down.

• To reduce the risk of potential injury or property damage:

• Cargo must be secured.

• Do not exceed cargo load rating of your vehicle.

• Secure all loads to truck utilizing cargo tie-downs.

• Extender should not be used as cargo tie-down.

•

When vehicle is in motion do not exceed 150 lbs (68 kg) load on the tailgate.

• The bed extender is not intended for off road use.

•

When not in use, the extender/divider should be in stowed or divider position

with the tailgate closed.

• When in use, all handles are to be in the locked position.

UTILITY

113

Page 118 of 196

TOW/HAUL MODE

•When driving in hilly areas, towing a trailer, carrying a heavy load, etc., and frequent

transmission shifting occurs, press the TOW/HAUL switch to select TOW/HAUL

mode. This will improve performance and reduce the potential for transmission

overheating or failure due to excessive shifting. When operating in TOW/HAUL mode,

transmission upshifts are delayed, and the transmission will automatically downshift

(for engine braking) during steady braking maneuvers.

• The “TOW/HAUL Indicator Light” will illuminate in the instrument cluster to

indicate that TOW/HAUL mode has

been activated. Pressing the switch a

second time restores normal operation.

If the TOW/HAUL mode is desired, the

switch must be pressed each time the

engine is started.

INTEGRATED TRAILER BRAKE MODULE

• The Integrated Trailer Brake Controller allows you to automatically or manuallyactivate the Electric Trailer Brakes and Electric Over Hydraulic Trailer Brakes for a

better braking performance when towing a trailer.

NOTE:

The Integrated Trailer Brake Controller is located in the center stack below the

climate controls.

• This module will have four different options depending on the type of trailer you want to tow and can be selected through the Electronic Vehicle Information Center

(EVIC) or touch-screen radio – if equipped.• Light Electric

• Heavy Electric

• Light EOH (Electric Over Hydraulic)

• Heavy EOH (Electric Over Hydraulic)

UTILITY

116

Page 122 of 196

DIESEL ENGINE BREAK-IN RECOMMENDATIONS

• The Cummins®turbocharged diesel engine does not require a break-in period due

to its construction. Normal operation is allowed, providing the following recom-

mendations are followed: • Warm up the engine before placing it under load.

• Do not operate the engine at idle for prolonged periods.

• Use the appropriate transmission gear to prevent engine lugging.

• Observe vehicle oil pressure and temperature indicators.

• Check the coolant and oil levels frequently.

•

Vary throttle position at highway speeds when carrying or towing significant weight.

NOTE:

Light duty operation such as light trailer towing or no load operation will extend the

time before the engine is at full efficiency. Reduced fuel economy and power may be

seen at this time.

• Because of the construction of the Cummins

®turbocharged diesel engine, engine

run-in is enhanced by loaded operating conditions which allow the engine parts to

achieve final finish and fit during the first 6,000 miles (10 000 km).

DIESEL ENGINE STARTING PROCEDURES

Engine Block Heater

• For ambient temperatures below 0°F (-18°C), engine block heater usage is recommended.

• For ambient temperatures below –20°F (-29°C), engine block heater usage is required.

• The engine block heater cord is routed under the hood to the right side and can be located just behind the grille near the headlamp.

• Connect the heater cord to a ground-fault interrupter protected 110–115 volt AC electrical outlet with a grounded, three-wire extension cord.

NOTE:

The block heater will require 110 volts AC and 6.5 amps to activate the heater element.

•The block heater must be plugged in at least one hour to have an adequate warming

effect on the coolant.

Water In Fuel Message

•

If a Water In Fuel message orindicator appears in the cluster and a chime

sounds five times, the fuel/water separator will need to be drained immediately to

prevent engine damage.

• Refer to “Draining Fuel Water Separator” in this guide for draining instructions or see your dealer.

DIESEL

120

Page 123 of 196

Cold Start Procedure

• Turn the ignition switch to the ON position. If the Wait To Start

light appears

in the cluster, wait for the light to turn off before starting.

• In extremely cold weather below 0°F (-18°C) it may be beneficial to cycle the manifold heaters twice before attempting to start the engine. This can be

accomplished by turning the ignition OFF for at least five seconds and then back

ON after the “Wait To Start Light” has turned off, but before the engine is started.

However, excessive cycling of the manifold heaters will result in damage to the

heater elements or reduced battery voltage.

• Refer to the Owner's Manual Diesel Supplement on the DVD for further details.

Engine Idling

• Avoid prolonged engine idling. Long periods of idling may be harmful to your engine because combustion chamber temperatures can drop so low that the fuel

may not burn completely.

• Incomplete combustion allows carbon and varnish to form on piston rings, engine valves, and injector nozzles. Also, the unburned fuel can enter the crankcase,

diluting the oil and causing rapid wear to the engine.

• If the engine is allowed to idle, under some conditions the idle speed may increase to 900 RPM then return to normal idle speed. This is normal operation.

WARNING!

Remember to disconnect the cord before driving. Damage to the 110–115 volt

electrical cord could cause electrocution.

DIESEL EXHAUST BRAKE (ENGINE BRAKING)

• The exhaust brake feature will only function when the driver presses the exhaustbrake switch.

• The switch is located on the switch bank below the audio system.

• Your vehicle is also equipped with the Smart Brake feature.

• This feature will automatically provide a variable amount of engine braking in an attempt to maintain a constant vehicle speed.

• The Smart Brake is activated by pressing the exhaust brake switch twice. The first press activate the full strength brake, second press activates the Smart Brake and

third press turns the brake off.

• The Smart Brake target vehicle speed is set when either the vehicle brake or the throttle pedal is released.

• Exhaust braking is most effective when the engine RPM is higher.

NOTE:

For optimum braking power, it is recommended to use the exhaust brake while in

TOW/HAUL mode.

DIESEL

121

Page 125 of 196

ENGINE MOUNTED FUEL FILTER/WATER SEPARATOR

Draining Fuel/Water Separator

•

If the “Water in Fuel” indicator lightis illuminated and an audible chime is

heard five times, you should stop the engine and drain the water from the separator.

• The drain is located on the bottom of the Fuel Filter and Water Separator assembly which is located on the driver's side of the engine.

• Turn the drain valve (located on the side of the filter) counterclockwise 1/4 turn, then turn the ignition switch to the ON/RUN position to allow any accumulated

water to drain.

• When clean fuel is visible, close the drain and switch the ignition to OFF.

• Refer to the Owner's Manual on the DVD for further details.

Fuel Filter Replacement

• With the engine off and a drain pan under the fuel filter drain hose, open the water drain valve 1/4 turn counterclockwise and completely drain fuel and water into the

approved container.

• Close the water drain valve and remove the lid using a socket or strap wrench; rotate counterclockwise for removal. Remove the used o-ring and discard it.

• Remove the used filter cartridge from the housing and dispose of according to your local regulations.

• Wipe clean the sealing surfaces of the lid and housing and install the new o-ring into ring groove on the filter housing and lubricate with clean engine oil.

• Install a new filter in the housing. Push down on the cartridge to ensure it is properly seated. Do not pre-fill the filter housing with fuel.

• Install the lid onto the housing and tighten to 22.5 ft lbs (30.5 N·m). Do not overtighten the lid.

• Start the engine and confirm no leaks are present.

The engine mounted filter housing is equipped with a No-Filter-No-Run (NFNR)

feature. Engine will not run if:

1. No filter is installed.

2.

Inferior/Non-approved filter is used. Use of OEM filter is required to ensure vehicle

will run.

CAUTION!

•Diesel fuel will damage blacktop paving surfaces. Drain the filter into an appro-

priate container.

•Do not prefill the fuel filter when installing a new fuel filter. There is a possibility

debris could be introduced into the fuel filter during this action. It is best to install

the filter dry and allow the in-tank lift pump to prime the fuel system.

•If the “Water In Fuel Indicator Light” remains on, DO NOT START the engine

before you drain water from the fuel filter to avoid engine damage.

DIESEL

123

Page 126 of 196

UNDERBODY MOUNTED FUEL FILTER/WATER SEPARATOR

Draining Fuel/Water Separator

•

If the “Water in Fuel” indicator lightis illuminated and an audible chime is

heard five times, you should stop the engine and drain the water from the separator.

• The drain is located on the bottom of the Fuel Filter and Water Separator assembly which is located in front of the rear axle above the drive shaft. The best access to

this water drain valve is from under the vehicle.

• Turn the drain valve (located on the side of the filter) counterclockwise 1 full turn, then turn the ignition switch to the ON/RUN position to allow any accumulated

water to drain.

• When clean fuel is visible, close the drain and switch the ignition to OFF.

• Refer to the Owner's Manual on the DVD for further details.

Underbody Fuel Filter Replacement

• With the engine off and a drain pan under the fuel filter drain hose, open the water drain valve 1 full turn counterclockwise and completely drain fuel and water into

the approved container.

• Close the water drain valve and remove the lid using a socket or strap wrench; rotate counterclockwise for removal. Remove the used o-ring and discard it.

• Remove the used filter cartridge from the housing and dispose of according to your local regulations.

• Wipe clean the sealing surfaces of the lid and housing and install the new o-ring into ring groove on the filter housing and lubricate with clean engine oil.

• Install a new filter in the housing. Push down on the cartridge to ensure it is properly seated. Do not pre-fill the filter housing with fuel.

• Start the engine and confirm no leaks are present.

The underbody mounted filter housing will cause the engine not to run if:

1. No filter is installed.

NOTE:

• Using a fuel filter that does not meet the manufacturer's filtration and water separating requirements can severely impact fuel system life and reliability.

• The WIF sensor is re-usable. Service kit comes with new o-ring for filter canister and WIF sensor.

DIESEL

124

Page 127 of 196

CAUTION!

•Diesel fuel will damage blacktop paving surfaces. Drain the filter into an appro-

priate container.

•Do not prefill the fuel filter when installing a new fuel filter. There is a possibility

debris could be introduced into the fuel filter during this action. It is best to install

the filter dry and allow the in-tank lift pump to prime the fuel system.

• If the “Water In Fuel Indicator Light” remains on, DO NOT START the enginebefore you drain water from the fuel filter to avoid engine damage.

ADDING FUEL – DIESEL ENGINE ONLY

• Your vehicle is equipped with a cap-less fuel system.

• Most fuel cans will not open the flapper door.

• A funnel is provided to open the flapper door to allow emergency refueling with afuel can.

Emergency Fuel Can Refueling

1. Retrieve funnel from the jack storage area under the passenger seat.

2. Insert the funnel into same filler pipe opening as the fuel nozzle.

3. Ensure the funnel is inserted fully to hold flapper door open.

4. Pour fuel into funnel opening.

5. Remove the funnel from filler pipe, clean off prior to putting back in the jack storage area under the passenger seat.

EXHAUST REGENERATION

• Under certain conditions, your Cummins®diesel engine and exhaust after-

treatment system may never reach the conditions required to remove the trapped

particulate matter. If this occurs, the “Exhaust System — Regeneration Required

Now” message will be displayed on the EVIC screen in your cluster and you will

hear one chime to alert you of this condition. Driving your vehicle at highway

speeds for as little as 45 minutes can remedy the condition and allow the engine

and exhaust after-treatment system to remove the trapped particulate matter.

• PLEASE NOTE: Under typical operating conditions, NO indications of regenera- tion state will be displayed. If you do reach 80% of filter capacity, the following

messages will assist you in inducing and understanding the regeneration process.

DIESEL

125